Reparații

- Hidraulica SRL oferă servicii de proiectare pentu orice componentă sau sistem hidraulica sau pneumatic. Oferim în principal reparați la sediul nostru, dar pentru evaluarea situației efectuăm deplasări la locația clientului. Procesul de reparație este simplu:

- Contactați-ne pentru a afla dacă reparația intră în aria noastră de acțiune.

- Aduceți-ne echipamentul dvs.

- Vom dezasambla și vom curăța sistemul pentru inspecție: verificăm toleranțele la părțile cu precizie, și realizăm un deviz pentru schimbarea pieselor uzate, distruse sau lipsă.

- Realizăm o ofertă corectă pentru efectuarea reparației.

- După acceptul clientului, echipamentul este curățat din nou, toleranțele sunt reverificate și unitatea este pregătită pentru reparație: suprafețele de contact sunt recondiționate sau înlocuite, garniturile, rulmenții și celelalte componente uzate sunt schimbate.

- În cazul unor componente distruse care nu se mai produc, noi le putem reproduce pe baza unui releveu sau putem oferi soluții eficiente din punct de vedere al costului dar și funcționalității. După reasamblare echipamentul este pregătit pentru testare statică și dinamică pentru a atinge parametrii necesari funcționări.

- Dacă optați să nu reparați echipamentul, anunțați-ne prin ce metoda doriți să vi-l retrimitem. În funcție de echipament, costuri adiționale pentru testare, dezasamblare sau casare pot fi percepute.

Reparații cilindri hidraulici și cilindrii pneumatici

-

Diametre de prelucrare de până la ∅800 mm, alte dimensiuni la cerere

-

Lungimi standard de prelucrare până la 13 m, alte lungimi la cerere.

-

Garnituri produse instant

Avem capacitatea și cunoștințele necesare pentru a repara orice tip de cilindru pneumatic sau hidraulic într-un timp scurt. Cu un stoc complet de componente și materie primă pentru prelucrare putem face față oricărei soicitări în regim de urgență. Departamentul nostru de etanșări vă pune la dispoziție garnituri din stoc sau în cazul unor profiluri speciale cu dimensiuni și materiale caracteristice vi le putem produce în doar câteva minute.

Reparația unui cilindru în cele mai multe cazuri împlică schimbarea etanșăriilor și ghidajelor, însă poate necesita și schimbarea corpului, tijei sau oricărei alte componente. Suntem pregătiți pentru orice operațiune este necesară în vederea aducerii cilindrului la parametrii inițiali. Pentru a reduce costurilor, încercăm să salvăm toate părțile viabile ale unui cilindru și să le refolosim în procesul de reparare.

Avantajul pe care îl deținem și de care puteți beneficia este că putem modifica designul inițial și putem să îl modernizăm pentru al face ai potrivit aplicațeiei dvs.

Branduri de produse pe care le reparăm sunt: Hidraulica, Bosch Rexroth, Parker, Vickers, Eaton, Liebherr, Mitsubishi, Moog, Haenchen, Binotto, Meiller, Hyva, Hainzl, Atos, Enerpac și orice alt tip de cilindru.

Pompe Hidraulice

Reconstruim pompe hidraulice

-

Termene de livrare scurte pentru kituri de reparație

-

Componente originale și after – market – la decizia clientului

-

Pompe hidraulice standard și de înaltă presisune

We are specialized in repairing multiple types of hydraulic pumps like axial piston pumps, radial piston pumps, manual pumps, vane pumps, ultra high pressure pumps – pumps with fixed or variable displacement, for open or closed loop system, for industrial or mobile machines. Gear pumps will not be repaired, new units will be offered. And not only the pumps can be the source of the problems so we take care also about the accessories like control valves, bell housings, couplings, hoses, filters a.s.o.

Due the good relations we have with our suppliers, we generally manage to provide the needed repair kits in short time and restart your machine. Our philosophy is to offer to the customer the choice of original or high quality aftermarket pieces used in the repair – not influencing the warranty we offer.

Every repaired pump is checked on the test bench. Exceptions can appear in special cases, when the pump is tested directly at the customer in our presence.

Because the pump is the heart of every hydraulic system, but it’s life is influenced by the oil we offer also fluid analysis, filters and hydraulic oil.

Usual brands we repair: Bosch, Rexroth, Hydromatik, Brueninghaus, Parker, Denison, Commercial, Vickers, Eaton, Linde, Uchida, Kawasaki, Caterpillar, Komatsu, Hitachi, Bucher, Sauer, Danfoss, Liebherr, Oilgear, Moog, Poclain, Sunfab, Volvo, Hawe, Casappa, Enerpac.

Hydraulic and Pneumatic Motors

We rebuild your hydraulic motor

-

Short delivery term for various common model repair kits

-

Original and aftermarket parts – customer’s decision

We are specialized in repairing multiple types of hydraulic motors like axial piston motors, radial piston motors, vane motors – motors with fixed or variable displacement, for open or closed loop system, for industrial or mobile machines. Gear motors will not be repaired, new units will be offered. Together with the pump we check and repair also the complementary valves mounted on the motor and we take care about the accessories like control valves, couplings, torque arms, hoses, filters a.s.o.

Due the good relations we have with our suppliers, we generally manage to provide the needed repair kits in short time and restart your machine. Our philosophy is to offer to the customer the choice of OEM or high quality aftermarket pieces used in the repair – not influencing the warranty we offer.

Every repaired motor is checked on the test bench. Exceptions can appear in special cases, when the motor is tested directly at the customer in our presence.

Usual brands we repair: Bosch, Rexroth, Hagglunds, Parker, Denison, Calzoni, Vickers, Eaton, Hydre-MAC, Linde, Uchida, Kawasaki, Staffa, Hitachi, Bucher, Danfoss, Liebherr, Poclain, Hawe, SAI.

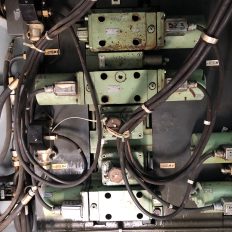

Hydraulic and Pneumatic Valves

Controlling Flow and Pressure

-

Needle valves up to 14.000 bar (200,000 psi)

-

Ball valves up to 1.400 bar (20,000 psi)

-

Ball and O-ring check valves – all pressure ranges and sizes

Valves are one of key elements in any high pressure system. This is why we focus on offering valves with maximum reliability and safety. Almost all needle and ball valves can be equipped with actuators: pneumatic, hydraulic and electric and electronic (for the micrometric valve).

• Needle valves can be delivered in various configuration, based on size, body design, stem type, actuation type. For controlling precisely the flow, we offer micrometering valves with manual or electric actuation by integrated microprocessor.

• Ball valves include several construction types: 2-way, 3-way, 4-way with various orifice sizes, but also the double block & bleed type. On request we can offer subsea valves (and subsea hoses).

• Check valves are available in many variants and sizes, for all pressure ranges and nominal diameters, for various fluids and temperatures – even for aggressive media or small-molecule gas.

Together we can find the suitable valve for your application or if needed, we can design and produce the needed one based on your special needs.

Proportional and Servo Valves

Accurate control

-

Pressure relief valves from 100 bar (1,500 psi) up to 5.170 bar (75,000 psi)

-

Rupture discs from 6,2 bar (90 psi) to 7.929 bar (115,000 psi)

• Pressure relief valves are designed to protect the system form pressure increase. They are used for liquids and gases and are offered in multiple construction types (metal seat or soft seat) with adjustable opening in defined ranges. For the safety of your application we deliver factory set, sealed and stamped. However, they are not suitable for continuous draining.

• Safety heads and rupture discs offer an economical and dependable relief port to guard against system over-pressure. they can be installed in any standard coupling.

Inconel is standard for the burst disc, but other materials are available, based on pressure, temperature and media.

Industrial Hydraulic Systems

Putting your production line on the feet

-

Reduce the number of tubes and adapters, create common body for multiple valves

-

Various connection types: NPT, BSP, SAE, JIC, Single Ferrule, Medium Pressure Cone and Thread, High Pressure Cone and Thread, Reverse Cone, FCC, QS and MPI.

Specialty pressure manifolds minimize space requirements and reduce the installation time necessary to plumb a pressure system. By reducing the number of components used in a system,also the potential leak joints are reduced. We can design and build pressure manifolds to meet specific requirements, capable of withstanding pressures from vacuum to 6.895 bar (100,000 psi) in standard and up to 14.000 bar on special request, and are available in a variety of materials and sizes.

Various connection types and sizes can be incorporated, together with special needle valves. We have the right solution for you.

Mobile Hydraulics

Keep your machine running

-

Pressure gauges up to 4.000 bar from stock, up to 7.000 bar and higher on request

-

Pressure transducers up to 5.000 bar standard, up to 16.000 bar on request

-

Thermocouples up to 10.000 bar and 600 °C. Higher temperatures on request

• Pressure gauges are available for pressure ranges up to 7.000 bar in different sizes. For high/low limit setting, electrical contact faces can be added for pressure control. Liquid filing, back or bottom connection are options. We recommend panel mounting for higher pressures.

• Pressure snubbers are recommended to be used for protecting gauges and instrumentation from pressure surges, pulsations and shocks. This will not compromise instrument accuracy or reaction time. Snubbers are offered in 1/4″ and 3/8″ sizes.

• Pressure transducers can be inserted directly in standard high pressure components. With various pressure ratings, process connection options and output electrical signals, we can find the best transducer for your application. For simple usage, we can provide you pressure transducer with USB connection, from vacuum up to 5.000 bar – software included.

• Thermocouples provide reliable temperature measurement within a fluid system, permitting direct temperature monitoring at any point with rapid response time. Having standard connections, these elements can be inserted in any standard item like tee or cross, on in the pressure vessel.

Industrial Tools

High Pressure Hydraulic Tools

-

High pressure line filter up to 4.137 bar (60,000 psi)

-

High flow filter: 1.380 bar (20,000 psi); 95 l/min nominal flow

• High pressure filters protect your system and increase the lifetime of components. We offer dual-disc line filters and cup-type line filters, both with replaceable filtering elements.

Standard filter elements: 5 … 65 micron. Various connection types and sizes available, from 1/4″ to 1″.

• High flow filters ensure proper filtration for high flows and medium pressure applications, with 95 l/min nominal flow. Maximum 10,000 psi or 20,000 psi operating pressures.

Standard filter elements: 2 … 20 micron. Various connection types and sizes available, from 1/4″ to 1″. Visual end electrical indicator available.

Ultra High Pressure Systems

Connecting Anything

-

Standard components up to 10.342 bar (150,000 psi), on request up to 14.000 bar (200,000 psi)

-

Various connection types: NPT, BSP, SAE, JIC, Single Ferrule, Medium Pressure Cone and Thread, High Pressure Cone and Thread, Reverse Cone, FCC, QS and MPI.

We offer a complete line of standard couplings, nipples, reducers and adapters, many of them from stock or with short delivery term, made from cold worked stainless steel or high strength steel. Specific materials are available on request.

We can design and manufacture special elements or manifolds to connect different types of connections and sizes in order to reduce the number of components used in the system. But remember, maximum pressure rating is based on the lowest rating of any component.